Absorbent Cotton Roll making plant and machineries With Bleaching

Product Details:

- Country Of Origin INDIA

- Power Source Electricity

- Operating Type Automatic

- Power 194000 Watt (w)

- Click to view more

Absorbent Cotton Roll making plant and machineries With Bleaching Price And Quantity

- 37000000.0 INR/Unit

- 1 Unit

Absorbent Cotton Roll making plant and machineries With Bleaching Product Specifications

- Automatic

- INDIA

- Electricity

- 194000 Watt (w)

Absorbent Cotton Roll making plant and machineries With Bleaching Trade Information

- Cash in Advance (CID)

- 1 Unit Per Week

- 90 Days

- Main Machine Body Wrapped in plastic, packed in a wooden crate Control Panel Thermocol + bubble wrap + wooden box Motors & Gearbox Packed in small wooden boxes Bleaching Unit Shrink-wrapped or crated separately Shafts & Rollers Covered in plastic and cloth Wires & Cables Rolled and packed in cartons Tools & Spares Boxed and labeled User Manual Kept in waterproof pouch

- All India

- ISO 9001 Quality system for your company ISO 13485 Needed for medical product manufacturing GMP Certificate Shows your factory is clean and safe Udyam / MSME Certificate For small business benefits Factory License Legal permission to run the factory Pollution Control Certificate Because of the bleaching unit Electric Safety Certificate For machine safety Boiler / Steam Certificate (if using steam) For the bleaching process IEC Code (Import Export Code) If you plan to export CE Mark (Optional) For export to Europe

Product Description

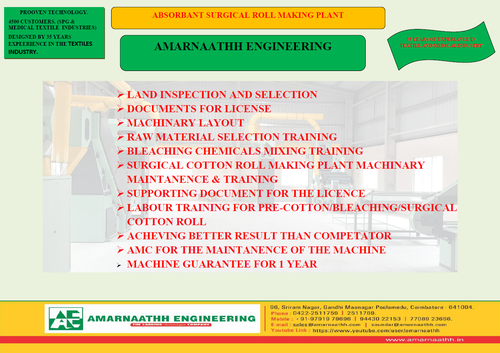

Our Absorbent Cotton Roll Making Plant with Integrated Bleaching System is a complete, high-efficiency solution for manufacturing high-quality medical-grade cotton rolls. Designed for seamless, end-to-end processing from raw cotton to finished, sterilized absorbent rolls this plant ensures hygiene, consistency, and compliance with international standards.

Plant Composition:

-

Cotton Opener Opens and loosens raw cotton for processing

-

Dust & Trash Remover Removes husk, seeds, and impurities

-

Bleaching Unit

-

SS 304/316 chemical tanks

-

Heating coils/steam jackets

-

Auto dosing system for hydrogen peroxide or other agents

-

Ensures uniform whitening and sterilization

-

-

Washing & Drying Section Rinses chemicals and dries the cotton using hot air or steam dryers

-

Carding Machine Aligns and combs the cotton fibers

-

Lap/Sliver Formation Prepares absorbent sheets or slivers

-

Cotton Roll Forming Machine Rolls processed cotton into desired width and diameter

-

Cutting & Packaging Machine Converts rolls into market-ready sizes with hygienic packaging

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+