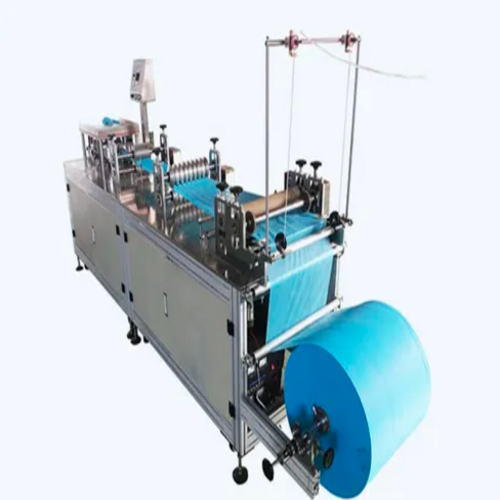

Bouffant Cap Making Machine

उत्पाद विवरण:

- वोल्टेज वोल्ट (v)

- फ़्रिक्वेंसी हर्ट्ज (एचजेड)

- प्रॉडक्ट टाइप

- पावर सोर्स

- ऑपरेटिंग टाइप

- सतह का उपचार

- वारंटी 1 Year

- Click to view more

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- हर्ट्ज (एचजेड)

- Industrial

- वोल्ट (v)

- 1 Year

व्यापार सूचना

- THOOTHUKUDI

- प्रति महीने

- हफ़्ता

- No

उत्पाद विवरण

A bouffant cap making machine is a specialized textile machine designed for producing bouffant caps which are widely used in healthcare food processing pharmaceuticals and other industries requiring sterile environments Bouffant caps are lightweight disposable head coverings made from nonwoven fabric designed to cover the hair and prevent contamination

Heres how a typical bouffant cap making machine works

Material Feeding The process starts with feeding a roll of nonwoven fabric typically made of polypropylene or similar lightweight materials into the machine The fabric is unwound and prepared for shaping

Cutting and Shaping The machine cuts the fabric into circular or semicircular pieces depending on the desired design and size of the bouffant cap This step ensures the material is the right size for forming the cap

Elastic Insertion An elastic band is fed into the machine which is then inserted around the edges of the fabric The elastic is typically inserted using an automatic elastic feeding mechanism ensuring the band is evenly distributed and securely sewn or welded into place

Forming the Cap The machine forms the bouffant shape by folding or pleating the fabric to create the puffed appearance that is characteristic of bouffant caps The pleats allow the cap to expand and cover the wearers head comfortably

Sealing and Finishing The edges of the fabric are sealed using ultrasonic welding heat sealing or stitching depending on the machine design This step ensures that the cap maintains its shape and prevents any fraying or unraveling

Inspection and Packaging The completed bouffant caps are inspected for quality ensuring that the elastic is securely attached and the fabric is free from defects After inspection the caps are folded and packaged for distribution

Bouffant cap making machines are highly automated and designed to produce large quantities of caps quickly efficiently and with consistent quality making them ideal for industries that require disposable head protection

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+