Textile Blow Room Step Cleaner

770000.0 INR/Piece

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 220 Volt (v)

- Surface Treatment Coated

- Weight (kg) 10 Tonne

- Click to view more

X

Textile Blow Room Step Cleaner Price And Quantity

- 1 Piece

- 770000.0 INR/Piece

Textile Blow Room Step Cleaner Product Specifications

- Other

- PISTA GREEN

- Electricity

- 10 Tonne

- 1 Year

- Other

- Coated

- 400 Kg/hr

- 220 Volt (v)

- Industrial

- Automatic

Textile Blow Room Step Cleaner Trade Information

- THOOTHUKUDI

- 3 Piece Per Month

- 3 Months

- No

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

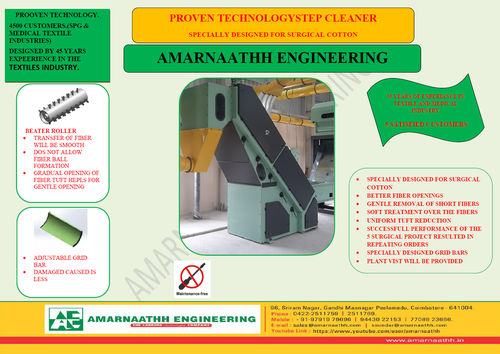

The Textiles Blow Room Step Cleaner is an essential part of the blow room line in textile manufacturing, designed to process raw cotton or other fibers by removing impurities, dust, and short fibers before the carding process. This machine significantly improves the quality of the final textile product by ensuring that the fibers are clean and properly prepared for further processing.

Key Features:

- High-Efficiency Fiber Cleaning: The step cleaner uses a combination of mechanical and air-based cleaning methods to effectively remove impurities such as dust, dirt, seeds, and short fibers from the raw material, ensuring that only high-quality fibers proceed to the next stage of production.

- Multi-Step Cleaning Process: The machine incorporates multiple cleaning stages, including beating, air suction, and separation. This multi-step process ensures that even the smallest particles and foreign matter are eliminated, improving the overall cleanliness of the fibers.

- Adjustable Cleaning Intensity: The intensity of the cleaning process can be adjusted to suit different types of raw materials or specific production requirements. Whether processing cotton, wool, or synthetic fibers, the machine can be fine-tuned to achieve optimal results.

- Airflow-Based Cleaning: The step cleaner utilizes powerful airflow to separate lighter impurities from the fibers, enhancing the cleaning efficiency without damaging the fibers themselves. The air suction also helps to reduce dust in the working environment.

- Minimal Fiber Loss: Engineered to minimize fiber loss during the cleaning process, the machine ensures that the maximum amount of good-quality fiber is retained, enhancing overall production efficiency and reducing waste.

- High Capacity and Speed: The step cleaner is designed to handle large volumes of raw materials at high speeds, making it suitable for large-scale textile operations. It can process several tons of fiber per day, ensuring continuous production.

- Durable and Sturdy Design: Built with high-quality materials, the machine is durable and capable of withstanding the rigors of continuous operation in industrial environments. It is designed for long-term use with minimal maintenance requirements.

- User-Friendly Interface: The machine features a simple and intuitive control panel, allowing operators to easily adjust settings, monitor the cleaning process, and manage the operation with minimal training.

- Energy Efficient: Designed with energy-saving technologies, the step cleaner optimizes power usage while maintaining high performance, contributing to lower operational costs.

- Low Maintenance: The machine is engineered for easy access to key components, allowing for quick maintenance and cleaning, reducing downtime and keeping the blow room line running efficiently.

Applications:

- Cotton Processing: Removes seeds, dust, and short fibers from raw cotton before carding.

- Synthetic Fiber Processing: Can be adapted for cleaning polyester, nylon, or other synthetic fibers.

- Wool Processing: Suitable for cleaning wool and other natural fibers.

- Pre-Spinning Preparation: Ideal for use in blow room lines in textile mills as a preparatory machine for the spinning process.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email