Diaper Making Machine

100000000.0 INR/Piece

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 440 Volt (v)

- Surface Treatment Painted

- Dimension (L*W*H) 4 Yard

- Click to view more

X

Diaper Making Machine Price And Quantity

- 100000000.0 INR/Piece

- 1 Piece

Diaper Making Machine Product Specifications

- 5 Long Ton

- 440 Volt (v)

- 4 Yard

- Other

- 500 Kg/hr

- Electricity

- Automatic

- Painted

- PISTA GREEN

- Other

Diaper Making Machine Trade Information

- THOOTHUKUDI

- Cash Advance (CA)

- 3 Piece Per Month

- 3 Months

- No

- Contact us for information regarding our sample policy

- All India

Product Description

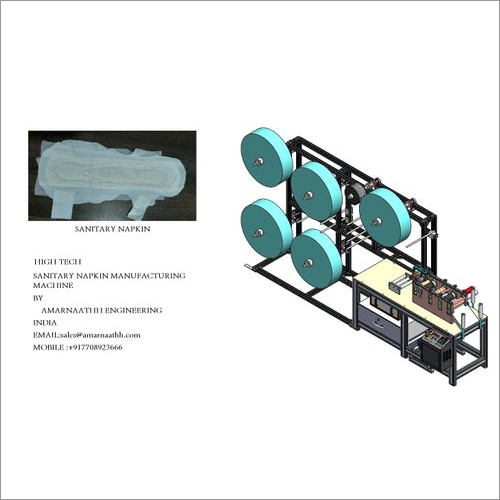

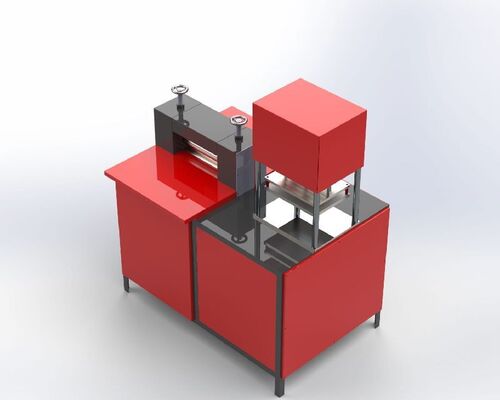

A Diaper Making Machine is a sophisticated piece of industrial equipment designed to produce disposable diapers for babies or adults. It automates the entire production process, ensuring efficiency, consistency, and hygiene while allowing for customization of diaper size, absorbency, and features. The machine integrates multiple raw materials into a finished product, handling tasks such as shaping, cutting, folding, sealing, and packaging.

Key Features and Process:

1. Raw Material Feeding System:

- The machine feeds essential materials such as:

- Non-woven fabric: Used for the top and bottom layers of the diaper, providing softness and comfort.

- Fluff pulp and Super Absorbent Polymer (SAP): Form the absorbent core that holds liquid.

- Polyethylene (PE) film: The backsheet that prevents leakage.

- Elastic bands: For the waistband and leg cuffs to ensure a snug fit.

- Adhesive tapes or fasteners: For securing the diaper on the body

2. Absorbent Core Formation:

- The core of the diaper, responsible for absorbing liquids, is formed by combining fluff pulp with SAP. The machine evenly distributes these materials, ensuring optimal absorbency and liquid retention. Some machines may have an air-laid system for better core formation.

3. Non-Woven Fabric and Backsheet Application:

- Soft, breathable non-woven fabric is applied on the top side of the core (touching the skin) for comfort, while the PE film is attached to the back side to act as a waterproof barrier, preventing leakage.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email