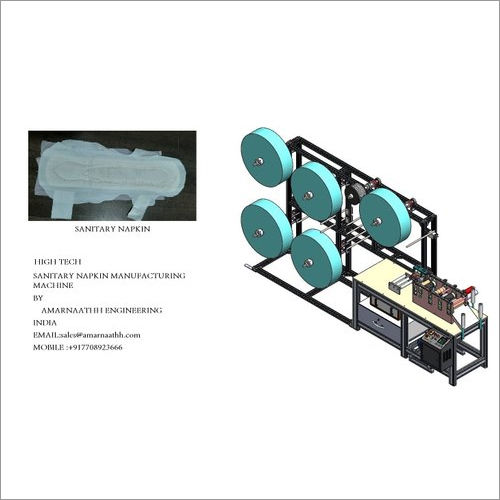

Sanitary Napkin Machine Fully Automatic

2500000.0 INR/Piece

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 6 Horsepower (HP)

- Surface Treatment Coated

- Color PISTA GREEN

- Click to view more

X

Sanitary Napkin Machine Fully Automatic Price And Quantity

- 2500000.0 INR/Piece

- 1 Piece

Sanitary Napkin Machine Fully Automatic Product Specifications

- Industrial

- Electricity

- Other

- 6 Horsepower (HP)

- 101 Tons/year

- Other

- 1 Year

- Automatic

- Coated

- PISTA GREEN

Sanitary Napkin Machine Fully Automatic Trade Information

- THOOTHUKUDI

- Cash Advance (CA)

- 3 Piece Per Month

- 3 Months

- No

- Middle East Africa Asia Australia Central America North America South America Eastern Europe Western Europe

- All India South India Central India West India North India East India Karnataka Kerala Lakshadweep Mizoram Meghalaya Gujarat Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa

Product Description

The Automatic Fully Sanitary Napkin Making Machine is an advanced, high-speed machine designed for the mass production of high-quality sanitary napkins. This machine automates the entire process from raw material feeding to final packaging, ensuring efficiency, precision, and hygiene in the production of sanitary products. It is ideal for manufacturers looking to produce a variety of sanitary napkin sizes and types while maintaining strict quality standards.

Key Features:

- Fully Automated Production: The machine handles all stages of sanitary napkin production, including raw material feeding, shaping, adhesive application, cutting, sealing, and packaging. This full automation minimizes labor involvement, increases production speed, and ensures consistent quality across all products.

- Multi-Layer Construction: The machine is equipped to assemble and bond multiple layers of materials, including the absorbent core, top sheet, and back sheet, using advanced bonding techniques such as thermal sealing or ultrasonic welding. This ensures a high level of absorbency and comfort in the final product.

- High-Speed Operation: With the capacity to produce thousands of sanitary napkins per hour, the machine is designed for large-scale manufacturing. Its high-speed capabilities increase production efficiency and help meet the demands of high-volume markets.

- Customizable Napkin Sizes and Types: The machine can produce various types and sizes of sanitary napkins, such as ultra-thin, regular, or night-use napkins. It allows for flexibility in shape, length, and absorbency, catering to different consumer preferences and market requirements.

- Precise Material Control: Advanced control systems ensure precise material feeding and positioning, preventing waste and ensuring that each napkin is made to exact specifications. This includes accurate application of the adhesive strips and wings for maximum comfort and fit.

- Hygienic Design: The machine operates in a fully enclosed system, minimizing contamination risks and ensuring that the sanitary napkins are produced in a clean, sterile environment. The entire process adheres to stringent hygiene standards, making the machine suitable for the production of health-related products.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email